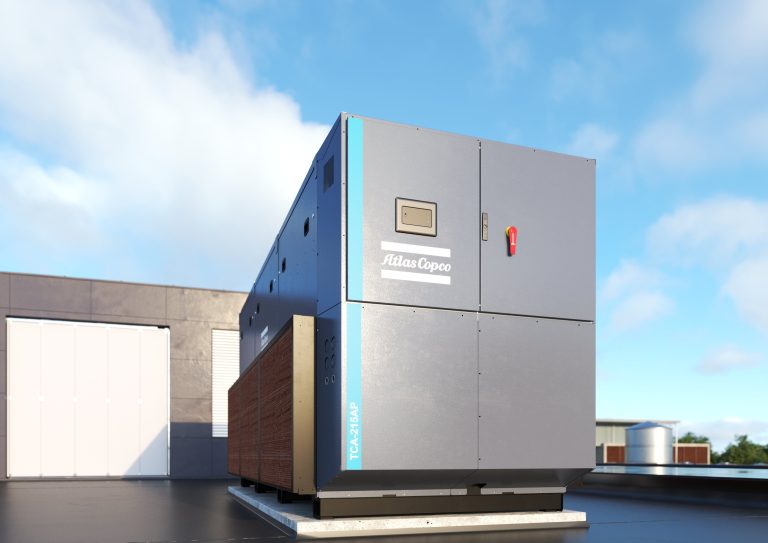

Atlas Copco Chillers and coolers

Atlas Copco chillers & cooling solution supplied and installed by Jll Leach from our Birmingham, Stoke and Shrewsbury depots.

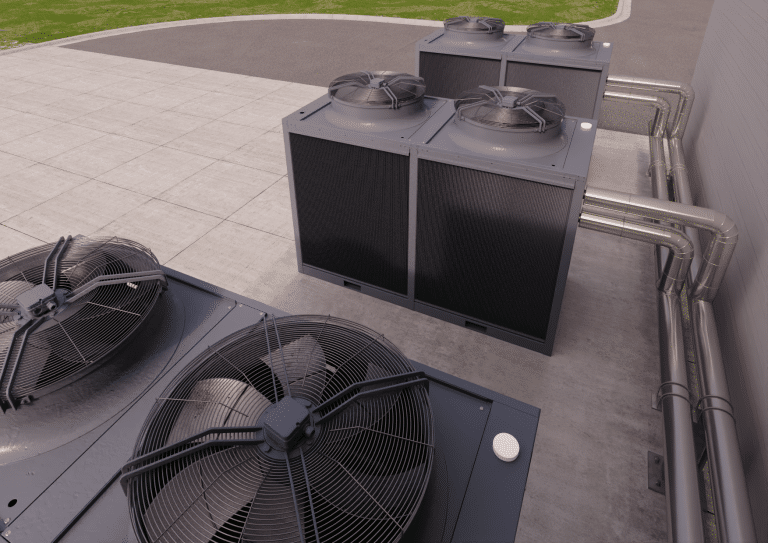

Industrial Chillers and Coolers

Highly efficient industrial air-cooled water chillers. Atlas Copco chillers are robust and reliable, and are engineered with the latest in-house technology. 15 models avalable with capacities from 4Kw to 90Kw.