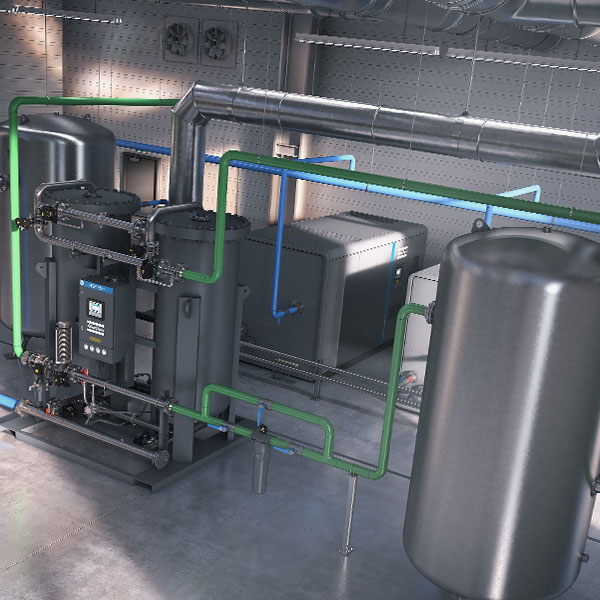

Atlas Copco Nitrogen Generators

Atlas Copco Nitrogen Generators supplied and installed by Jll Leach. Why use bottled gas when you can generate your own nitrogen on site?

Nitrogen Generators

Supply and install of Atlas Copco Nitrogen Generation systems with either Membrane or Pressure Swing Adsorption technology. Covering the whole of the UK from our Stoke-on-Trent, Birmingham and Shrewsbury depots. Using compressed air, you can produce your own nitrogen on site, from 1 to 5000 Nm3/h and 95 to 99.999% purity.