Cheadle Air Compressor Servicing

Serving clients across the country from our three West Midlands depots, our engineers specialise in compressed air systems, automation, and steam power.

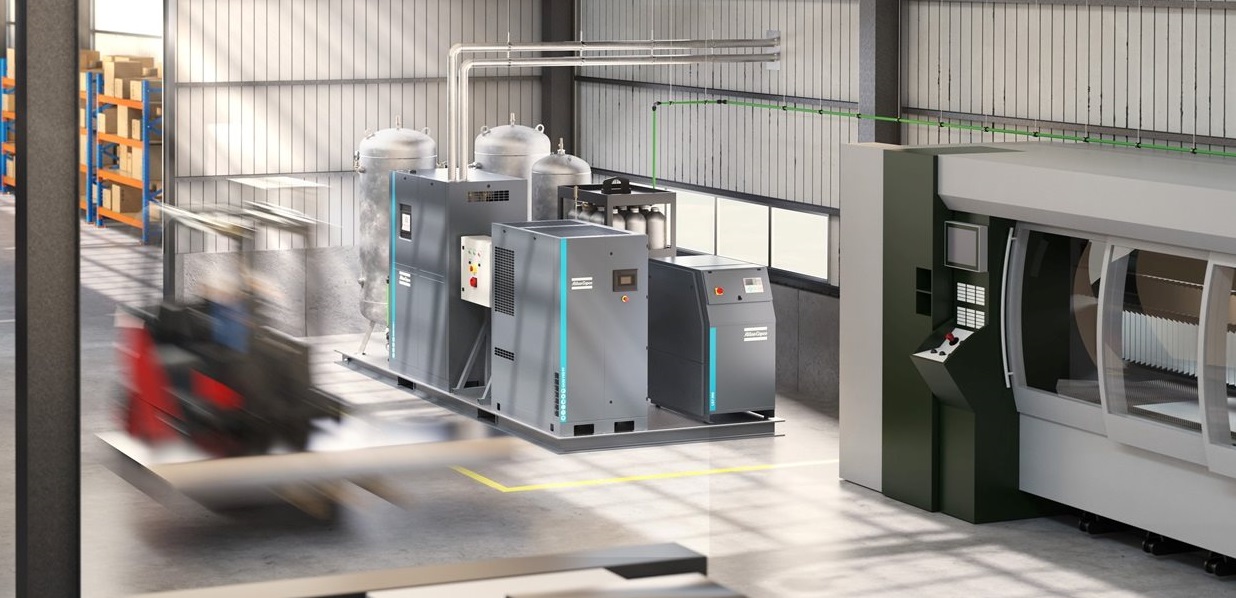

We partner with leading manufacturers like Atlas Copco, Festo, and Spirax Sarco, and offer servicing and maintenance on any brand of equipment. If you need compressed air to power tools or support your industrial processes, you can depend on J Ll Leach to keep your system in the best possible working order.

Air Compressor Service & Repair in Cheadle

We offer a complete design and installation service. Our team has worked in every conceivable industrial sector, helping to meet their fluid power needs. If you need a new installation, or to upgrade your existing system, we will work with you to create a design that meets your needs, works with your existing processes, and suits your budget.

J Ll Leach can also manage your ongoing maintenance. Like our installation, our servicing matches your needs. We can provide original spare parts and maintenance as required, all the way up to fixed-price maintenance options that cover all your servicing and even round-the-clock callouts when required.

Cheadle: fabric, sportswear, and tourism

Cheadle’s association with fabric began in the 17th century. By the end of the 18th century, around three thousand people were employed in fabric trades, especially silk working. It was primarily a domestic industry at the time, but it became increasingly concentrated in factories as the Industrial Revolution arrived.

One example was Umbro, which had its headquarters in Cheadle until 2013. Their shirts feature in many iconic sporting moments, perhaps most famously the 1966 England football strip. Cheadle is now a popular tourist destination for its attractive town centre and as a base for venturing into the surrounding Peak District.

Compressed air in Cheadle

The textile industry may have started with homeworking, but it is a highly industrialised process today, and compressed air plays a key role.

As well as powering tools, compressed air can be used to warm and cool fabrics at critical points, air knives can be used to manipulate material, and air jet looms are used to make the fabric itself. J Ll Leach can help you integrate whatever you need compressed air to do into your processes.

FREQUENTLY ASKED QUESTIONS

Why is compressed air leak detection important?

Leaks are inevitable, and often they can be so small, you cannot detect them. You notice only when the cumulative effect shows in lower pressure and higher costs. Regular ultrasonic leak detection identifies leaks early, allowing you to prioritise repair and typically pays for itself in reduced costs.

What is the best way to maintain my compressor?

Quite simply, it’s to have an appropriate service plan in place. This will include routine maintenance like oil and filter changes and system checks. Using trained engineers means that your system is kept in good order, and their regular inspections allow for prompt preventive maintenance when needed.

GET IN TOUCH

Our experienced team is waiting for your call. We work with businesses

of all sizes in every sector – get in touch today.

ADDRESS

J Ll Leach & Co Ltd Head Office

Etruscan Street, Etruria

Stoke on Trent,

ST1 5SE

Phone

01782 202001